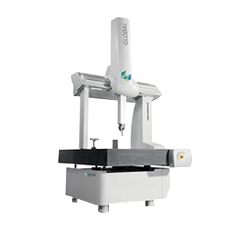

We provide In House Stationary CMM Inspection Services using Co-ordinate Measuring Machine. Our setup is situated in Aurangabad, Maharashtra, India.

• Range(in mm)- X:700 Y:1000 Z:700

• Accuracy- 1.7 um +2.8L/1000

Stationary CNC CMM (Accurate)

- Model-Cordimesur

- Accuracy-2.5+(L/350)µ

- Size-600X1000X500 (XXYxZ)

- First Article Inspection, Lot Inspection.

- Jig, Fixture, Relation Gauges, Dies & Moulds Inspection.

- CAD Model Comparison.

What is stationary cmm?

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe.. Depending on the machine, the probe position may be manually controlled by an operator or it may be computer controlled. CMMs typically specify a probe's position in terms of its displacement from a reference position in a three-dimensional Cartesian coordinate system (i.e., with XYZ axes). In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable.

Purpose of using Stationary CMM/Application

A common use of CMMs is in manufacturing and assembly processes to test a part or assembly against the design intent. In such applications, point clouds are generated which are analysed via regression algorithms for the construction of features. These points are collected by using a probe that is positioned manually by an operator or automatically via Direct Computer Control (DCC). DCC CMMs can be programmed to repeatedly measure identical parts; thus an automated CMM is a specialized form of industrial robot.

Product quality inspection.

Due to product processing shape becomes more and more complicated, higher and higher precision, the CMM gradually become the main fixture of the product quality inspection. It is used to issue all machining dimension inspection to ensure to provide qualified products to next working procedure. In each processing procedure, as long as there is a status change should send for CMM detection, such as replacement of tool, machining time or program. For extremely complex mechanical parts, traditional fixture already cannot satisfy the requirement of quality control, at the same time the processing and design of gauge becoming a difficult problem because of the complexity of the processing, so the Coordinate measuring machine become the main means of quality inspection.